6 Common Centrifugal Pump Efficiency Questions Explained

Centrifugal pump efficiency has a direct impact on energy use, operating costs and equipment lifespan. Most efficiency issues stem from a small...

Effective dewatering is critical to maintaining safe, productive mining operations, controlling groundwater ingress and protecting both personnel and equipment.

Well-designed dewatering systems control groundwater levels, protect infrastructure, and enable continuous operations. By reducing water ingress and dilution, mining operations can improve material quality, maintain stable working conditions, and protect long-term productivity.

Selecting the right dewatering pump starts with understanding site-specific conditions. Key considerations include:

Required flow rate and volume

Total Dynamic Head (TDH)

Water quality, including abrasiveness, solids content and corrosive elements

Beyond hydraulic performance, energy efficiency, ease of maintenance and spare parts availability play a major role in long-term operating costs. Pumps that are difficult to service or poorly matched to site conditions often lead to unnecessary downtime and higher lifecycle costs.

Different mining environments require different pumping solutions:

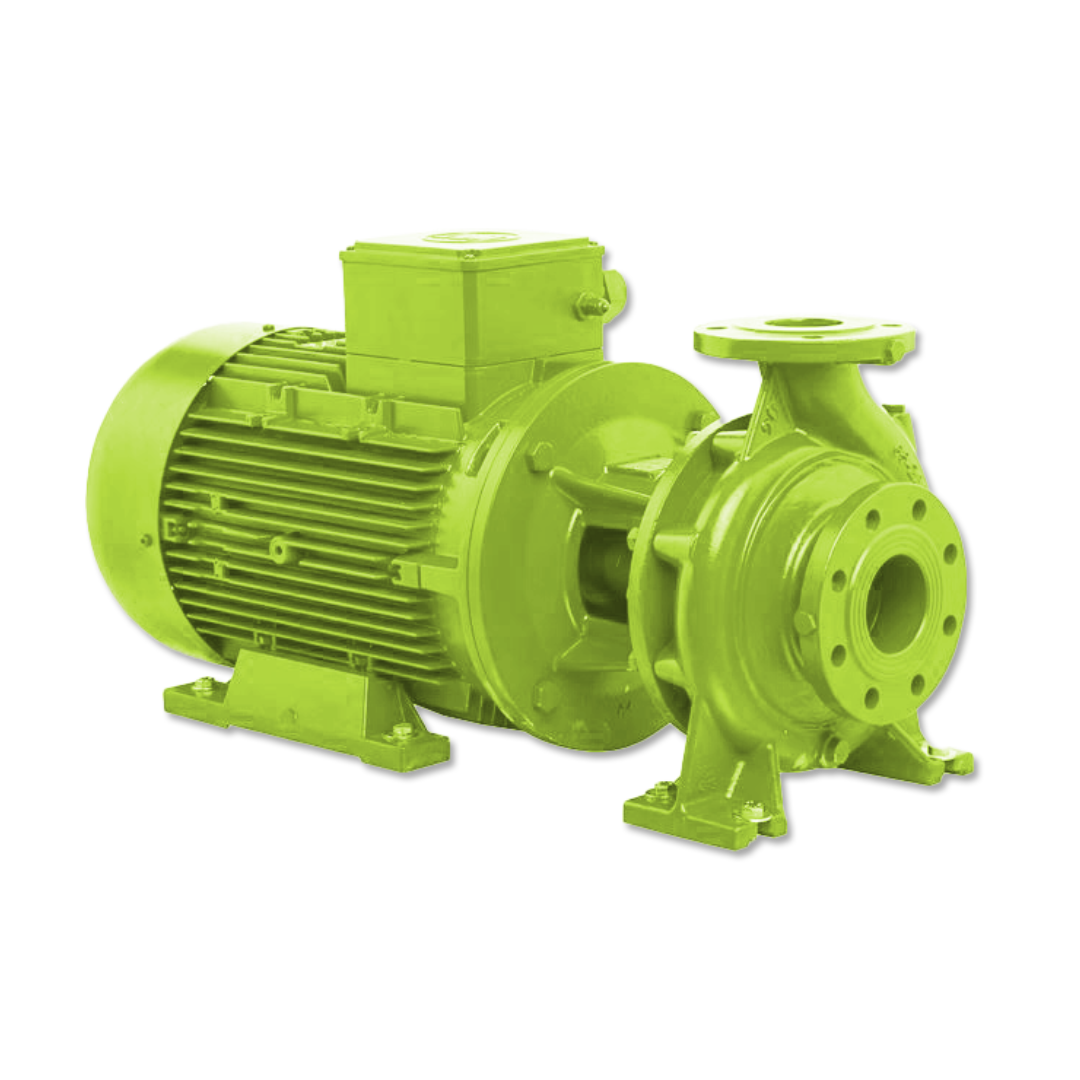

Centrifugal pumps are well suited to high-volume water transfer but may struggle with solids-laden or abrasive fluids if not correctly specified.

Submersible pumps operate effectively in deep or confined environments but require careful maintenance planning due to constant submersion.

Diaphragm pumps handle slurries, solids, and viscous fluids reliably, making them suitable for challenging conditions, albeit at lower flow rates.

The most effective solution balances performance, durability and serviceability based on the specific dewatering challenge.

Consistent maintenance is essential to keep dewatering systems operating reliably. Best practices include:

Routine inspection of wear components

Monitoring flow rates, pressure, and power consumption

Keeping pumps and suction lines clear of debris

Scheduling preventative maintenance before peak demand periods

Proactive monitoring allows early identification of performance changes, reducing unplanned failures and extending equipment life.

Mining dewatering systems are increasingly incorporating automation and monitoring technologies. Smart controls and remote monitoring enable operators to respond quickly to changing water conditions and predict maintenance needs before failures occur.

Advances in materials and pump design are also improving durability in abrasive and corrosive environments, reducing replacement cycles and improving overall system reliability.

Mining operations that invest in modern, well-matched dewatering solutions are better positioned to improve efficiency, manage risk, and sustain productivity over the life of the site.

Centrifugal pump efficiency has a direct impact on energy use, operating costs and equipment lifespan. Most efficiency issues stem from a small...