Paint & Chemical

Pumps & Equipment

- Pumps engineered for corrosive, abrasive, and hazardous fluids

- Safe, leak-free containment for solvents, acids, resins, and pigments

- Chemical-resistant materials: 316SS, PVDF, PTFE & specialised elastomers

- Built for viscous, shear-sensitive, and abrasive product handling

- Designed for compliance with safety and environmental standards

.jpg?width=2000&height=898&name=BlueTeam_Hero%20(3).jpg)

.jpg?width=2000&height=898&name=BlueTeam_Hero%20(6).jpg)

-1.jpeg?width=2000&height=863&name=BlueTeam_Hero%20(7)-1.jpeg)

Chemical Resistant

Chemical Resistant

Leak-Free & Safe

Leak-Free & Safe

Handles Thick & Abrasive Fluids

Handles Thick & Abrasive Fluids

Compliance-Ready

Compliance-Ready

Reliable for Continuous Duty

Reliable for Continuous Duty

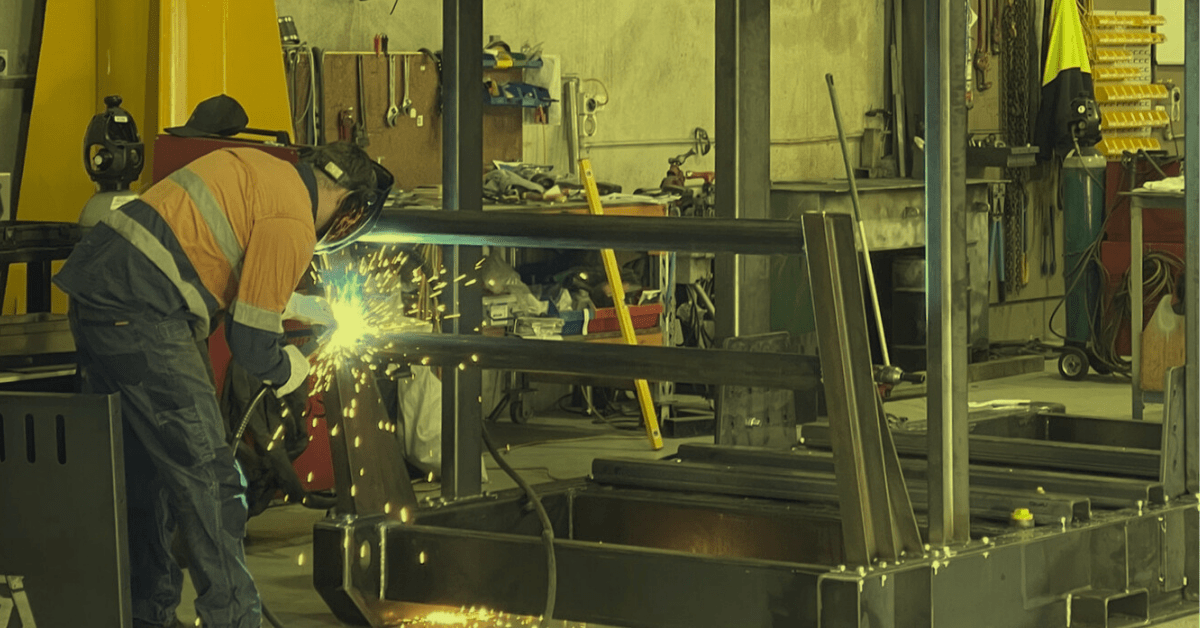

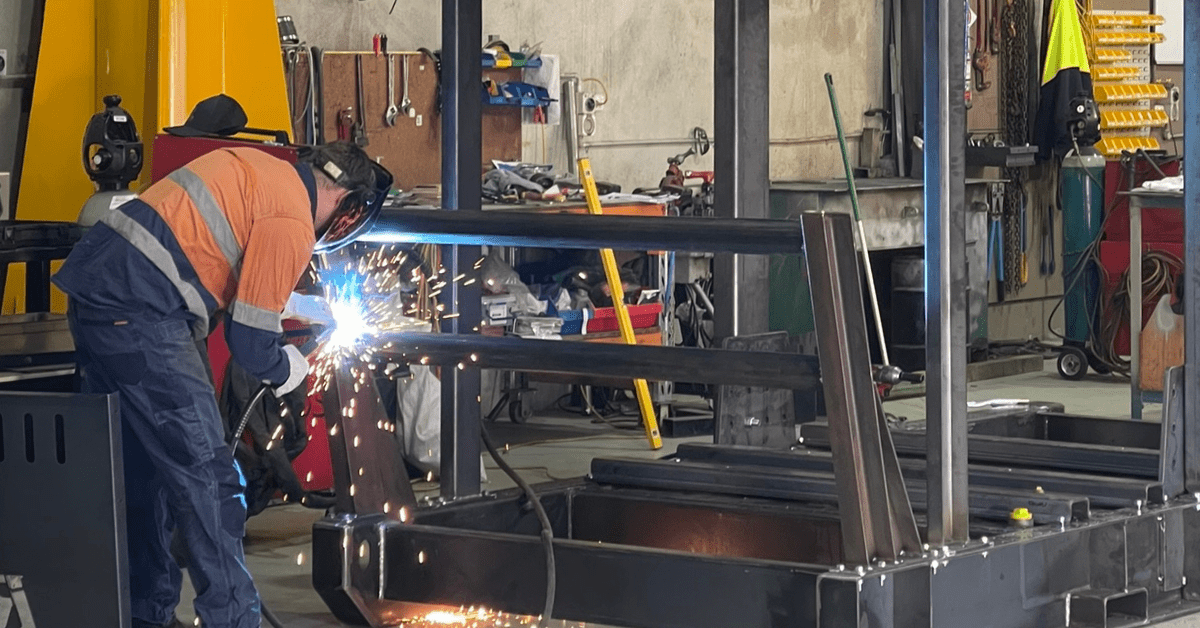

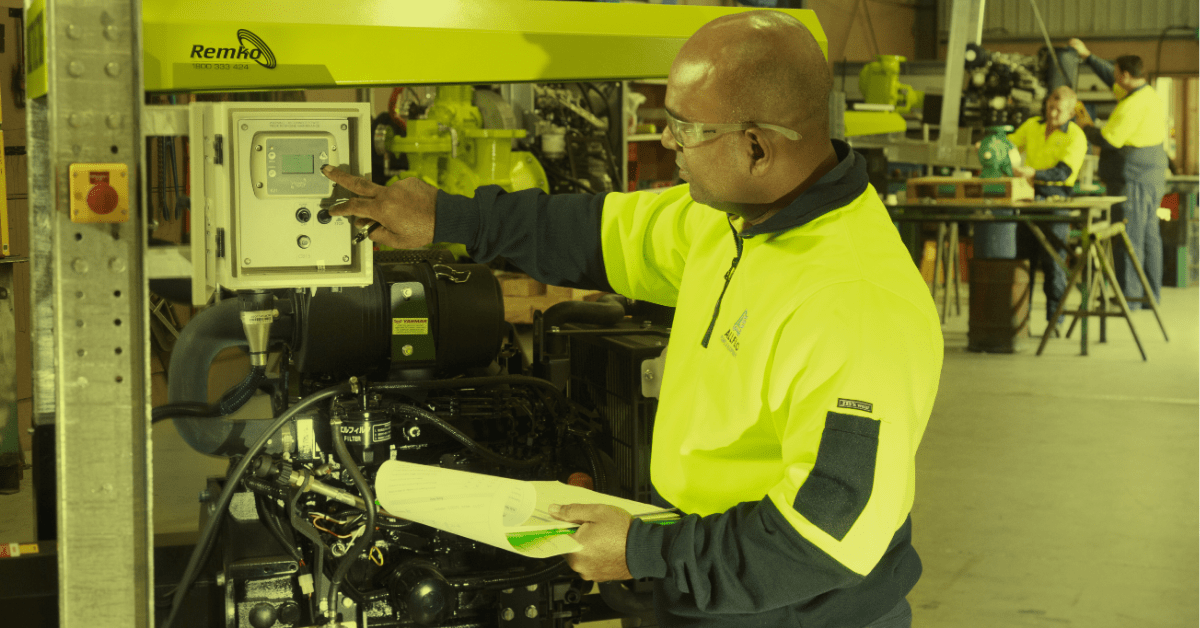

Built for corrosive environments. Designed for safety. Engineered for precision.

Built for corrosive environments. Designed for safety. Engineered for precision.

Paint and chemical processing involves complex fluids and strict safety requirements.

Allflo designs pumping systems that protect your people, products, and production schedules.

Our solutions ensure chemical compatibility, leak-free transfer, and reliable performance across corrosive, volatile, viscous, and abrasive applications — from raw material handling to waste management.

Pumps We Build for Paint & Chemical

- Corrosive & Hazardous Fluid Transfer

- Viscous Products, Resins & Coatings

- Metering, Dosing & Precision Control

- Mixing, Blending & Recirculation

- Waste, Effluent & Environmental Control

Waste, Effluent & Environmental Control

Pumps designed for chemical wastewater, washdown, slurries, and high-solids waste — supporting environmental compliance and safe discharge.

Explore products:

Mixing, Blending & Recirculation

Reliable pump systems for recirculation loops, pigment dispersion, inline blending, and tank-to-tank transfer in chemical and paint production lines.

Explore products:

Process & Utility Pumps

Reliable centrifugal and booster systems that support on-site water transfer, tank filling, and wash-down applications — built for everyday performance across civil construction environments.

Explore products:

Viscous Products, Resins & Coatings

Pumps engineered for thick, abrasive, or shear-sensitive media such as pigments, resins, adhesives, and coatings — delivering consistent, gentle flow.

Explore products:

Metering, Dosing & Precision Control

Accurate dosing solutions for additives, catalysts, activators, and chemical blends — supporting repeatable batching and controlled formulations.

Explore products:

What to expect from Allflo Pumps & Equipment

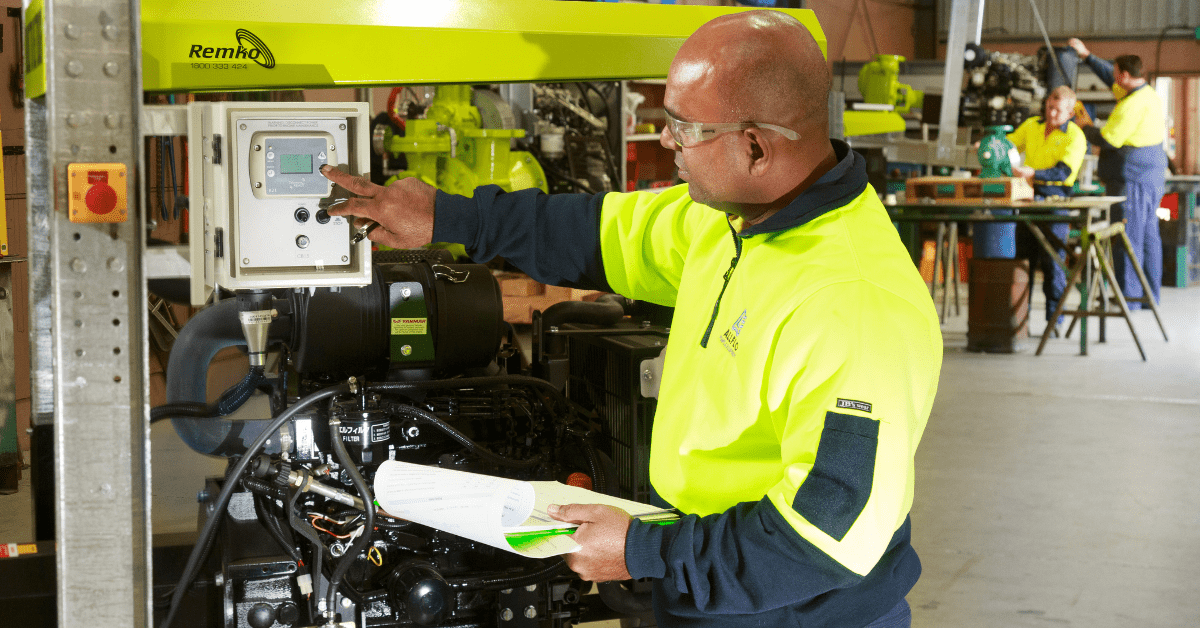

Engineered for Corrosion Resistance

Materials matched precisely to chemical composition, temperature, and exposure risk.

Safe, Leak-Free Operation

Mag-drive and diaphragm technologies eliminate seal failures and reduce workplace hazards.

Handles Thick & Abrasive Fluids

Designed for high-viscosity and solids-laden chemicals including resins, suspensions, and pigments.

Compliance-Focused Design

Supports environmental, handling, and containment regulations through engineered solutions.

Reliable Under Continuous Duty

Durable, low-maintenance systems built for demanding production schedules.

FAQ's

for Paint & Chemical

-

Can your pumps handle corrosive or hazardous chemicals?

Yes — including acids, solvents, caustics, volatile fluids, and Class 3/6/8 chemicals.

-

Do you supply pumps for pigments, resins, and viscous coatings?

Yes — with progressive cavity, lobe, gear, and specialty AODD pumps suited to thick or abrasive fluids.

-

Are your pumps leak-free for hazardous applications?

Yes — magnetic drive and sealed diaphragm technologies prevent leakage and enhance operator safety.

-

Do you support accurate chemical dosing and blending?

Absolutely — we supply metering, peristaltic, and diaphragm dosing systems with skid integration options.

-

Do you have pumps suited for chemical wastewater and disposal?

Yes — including submersible vortex, cutter, grinder, and chemical-resistant transfer pumps.

Businesses like yours are solving these challenges

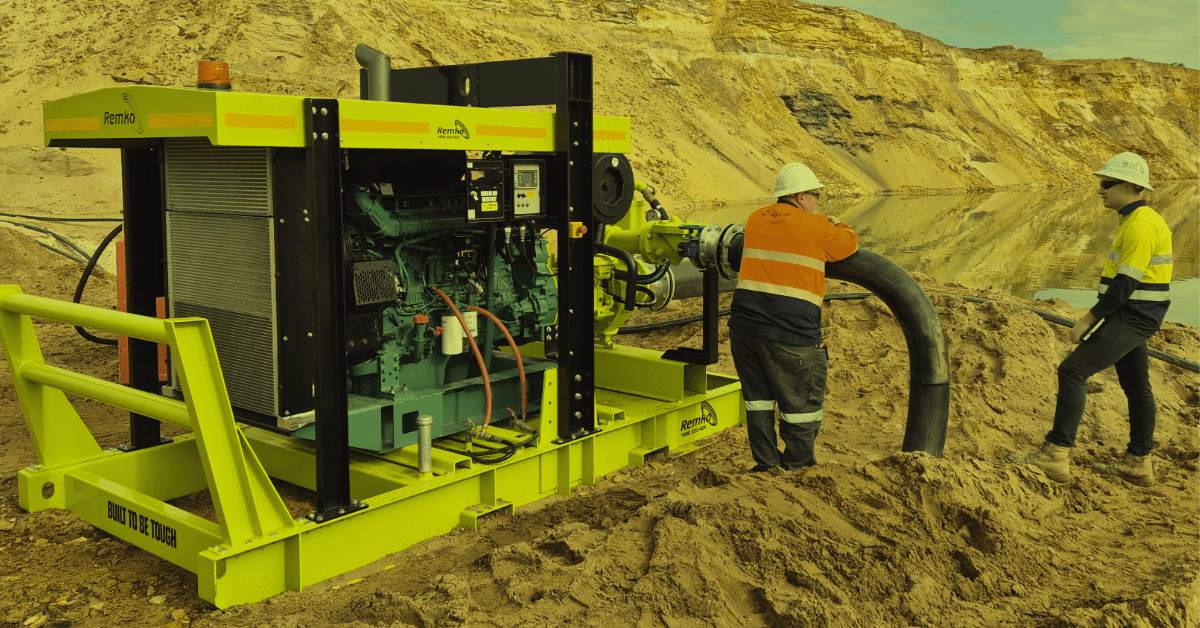

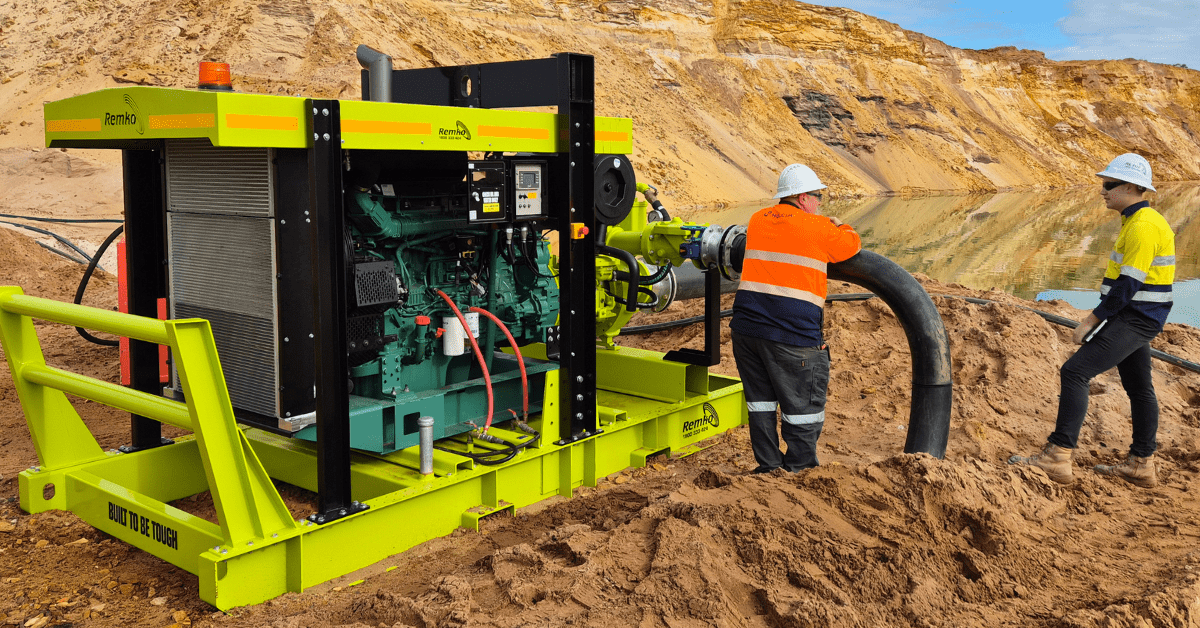

Quarry Site Efficiency Upgrade

Problem: Frequent pump breakdowns were delaying production.

Solution: Allflo supplied abrasion-resistant self-priming pumps.

Result: 40% reduction in downtime and servicing.

Custom Fire Water Storage Tank

Problem: A unique site footprint needed a space-efficient, compliant solution.

Solution: We delivered a customised & compliant tank with documentation.

Result: Full compliance and efficient use of space.

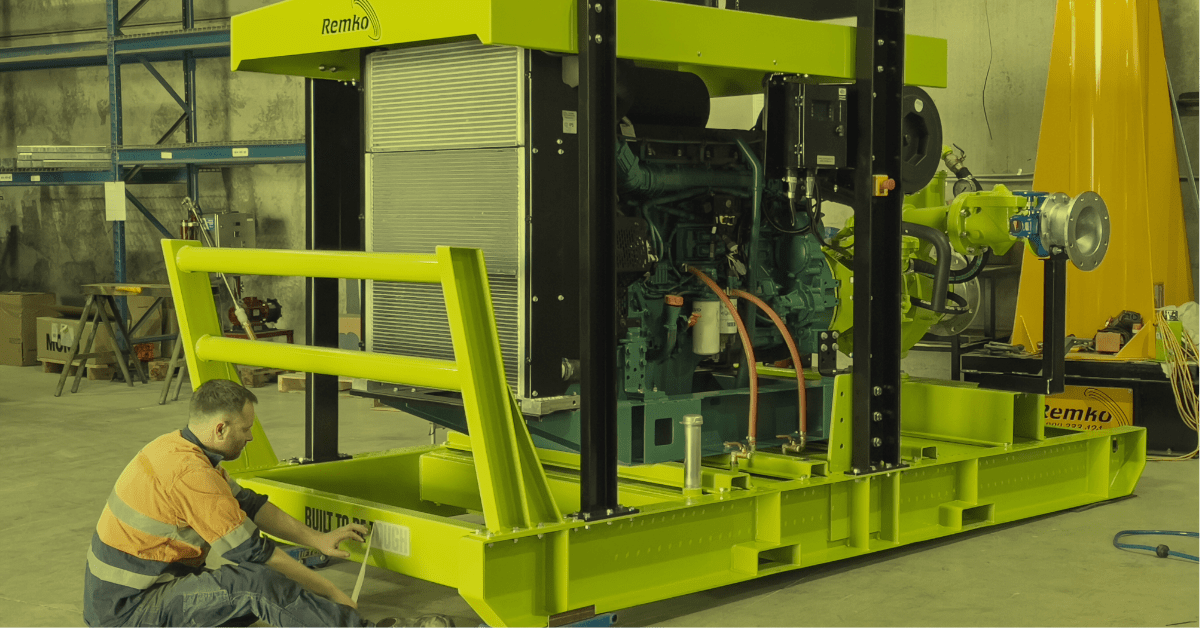

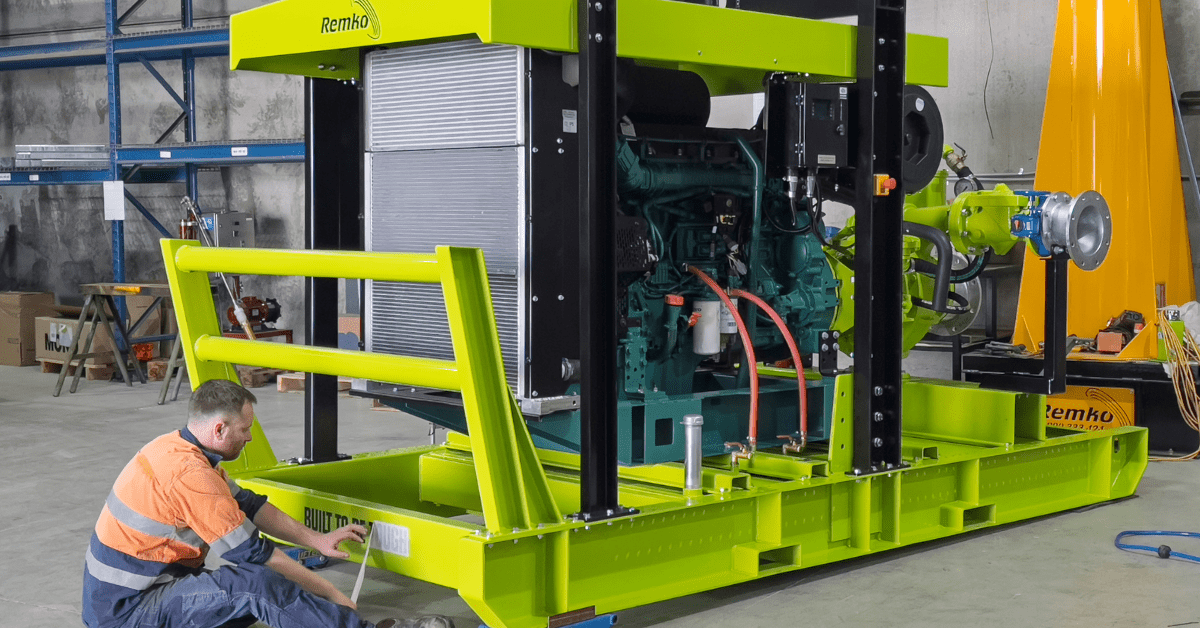

NT Mining Fire Protection System

Problem: A mining operation needed a fire system in extreme conditions.

Solution: Allflo delivered a diesel-driven fire system with remote monitoring.

Result: Reliable protection with site-specific performance.