Pulp, Paper & Timber

Pumps & Equipment

- Fibre, pulp and slurry transfer

- Chemical dosing and adhesive handling

- Effluent, wastewater and plant drainage

- Cooling, washdown and utility water

- Continuous-duty process performance

.jpg?width=2000&height=898&name=GreenTeam_Hero%20(28).jpg)

.jpg?width=2000&height=898&name=BlueTeam_Hero%20(2).jpg)

.jpg?width=2000&height=898&name=BlueTeam_Hero%20(1).jpg)

.jpg?width=2000&height=898&name=BlueTeam_Hero%20(6).jpg)

.jpg?width=2000&height=898&name=BlueTeam_Hero%20(8).jpg)

.jpg?width=2000&height=898&name=BlueTeam_Hero%20(7).jpg)

.jpg?width=2000&name=BlueTeam_Hero%20(7).jpg)

Handle fibrous slurries

Handle fibrous slurries

Chemical-safe design

Chemical-safe design

Continuous reliability

Continuous reliability

Effluent control

Effluent control

Local support

Local support

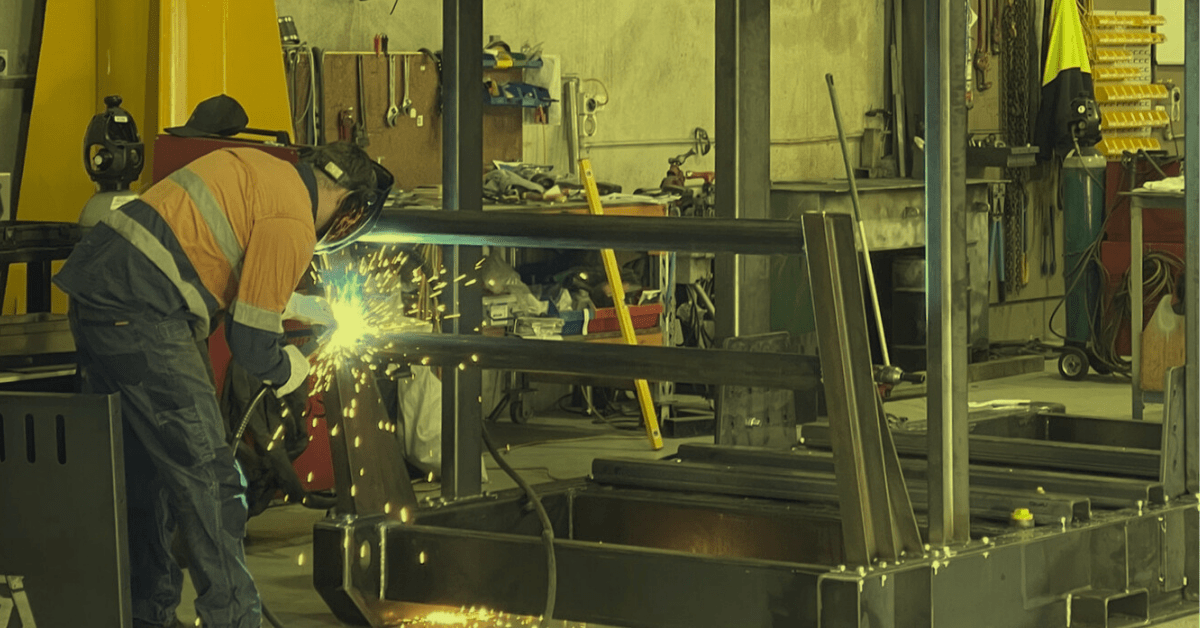

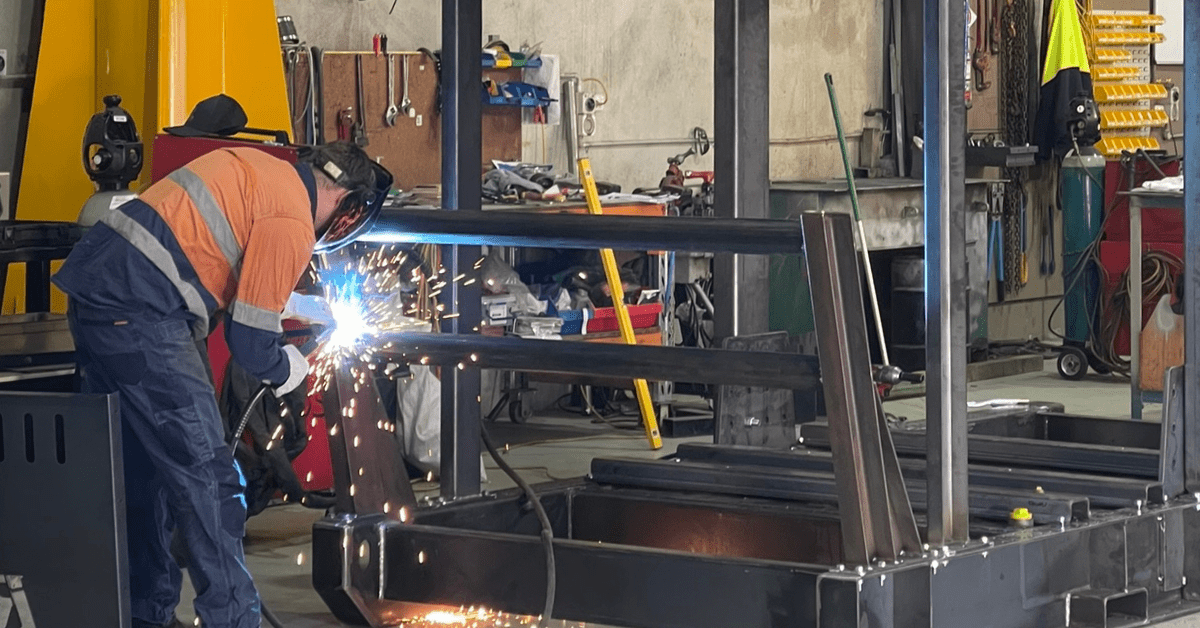

Reliable pumping systems for pulp, paper & timber processing

Allflo builds durable, chemical & slurry-handling pumping systems for fibre, pulp and process plants.

Designed for abrasive, fibrous and corrosive fluids, our pumps maintain reliable flow and uptime across demanding production environments.

Australian-assembled, compliance-ready and built for long-term use in mill and timber applications.

What we build for pulp, paper & timber processing

- Slurry & Process Pumps

- Chemical Handling Pumps

- Utility & Transfer Pumps

- Submersible & Drainage Pumps

- Diaphragm & Portable Pumps

- Process & Booster Systems

Utility & Transfer Pumps

Reliable general-duty systems for water supply, cooling, cleaning and washdown across pulp and timber facilities.

Explore products:

Chemical Handling Pumps

Corrosion-resistant systems for acids, alkalis and process chemicals used in bleaching, treatment and surface coating applications.

Explore products:

Process & Booster Systems

Centrifugal and positive-displacement systems that support general process transfer, tank filling and pressure control.

Explore products:

Submersible & Drainage Pumps

Pumps designed for wastewater, drainage and solids-laden effluent management — ensuring clean, compliant mill operations.

Explore products:

Diaphragm & Portable Pumps

Air-driven diaphragm systems for adhesive, ink, chemical and slurry transfer — ideal for flexible process use.

Explore products:

What to expect from Allflo Pumps & Equipment

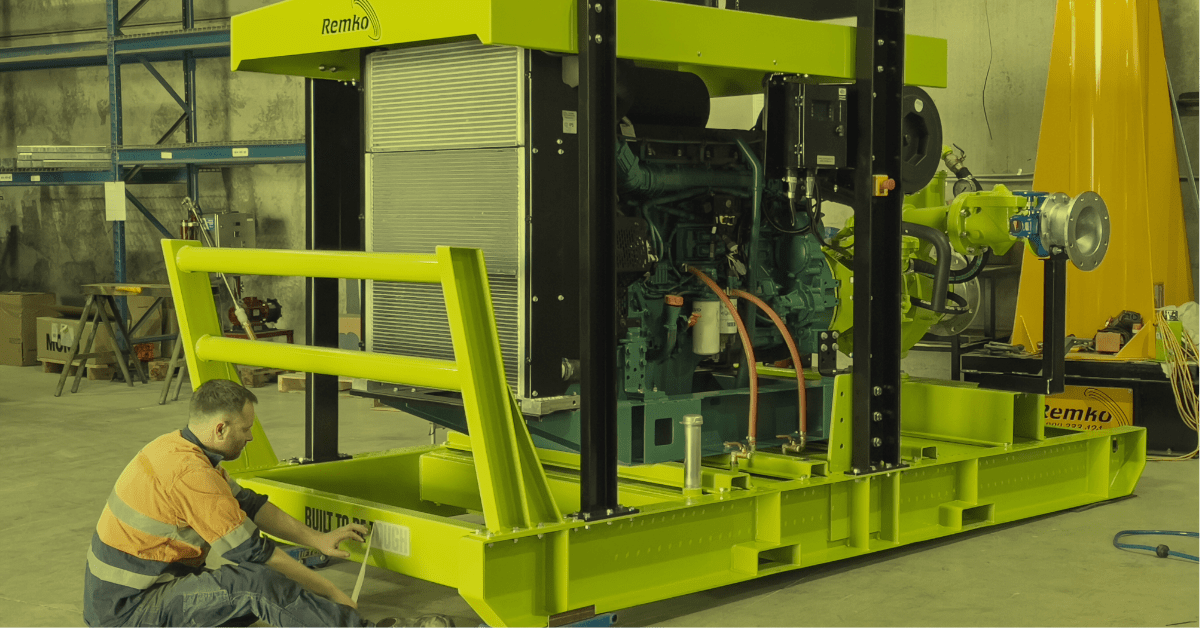

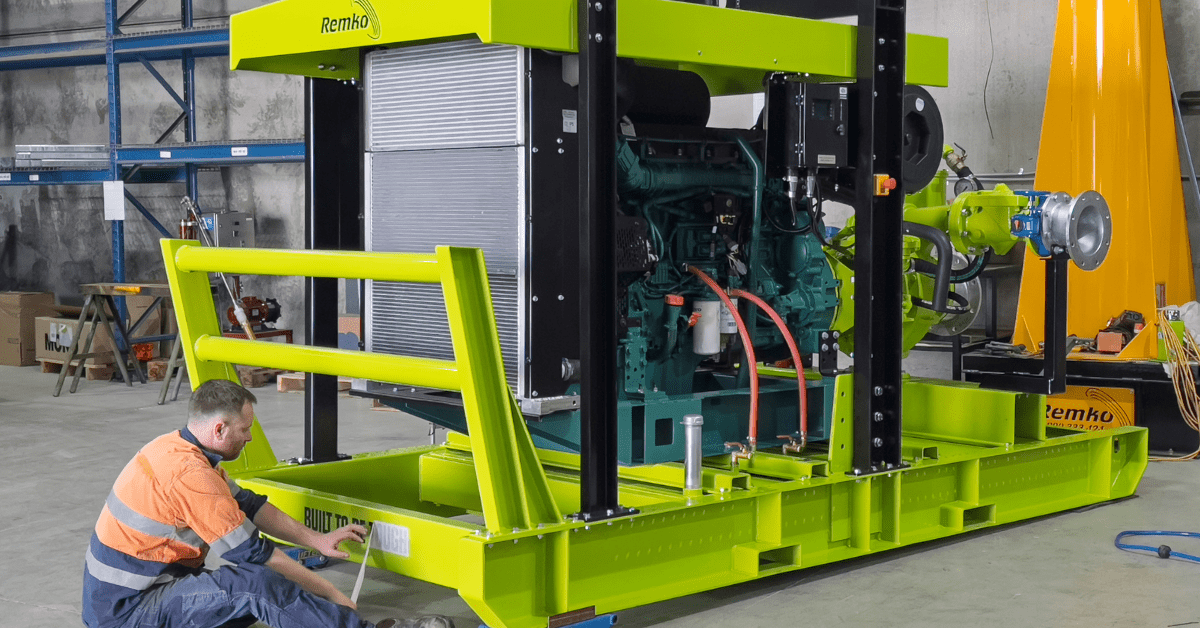

Built for Continuous Production

Allflo pumps are designed for abrasive, fibrous and chemical fluids under 24/7 operation — minimising maintenance and maximising uptime.

Built to perform, day after day.

Tailored to Your Process

Every system is custom-engineered for your plant layout, product viscosity and duty cycle — ensuring seamless operation and reduced downtime.

Right configuration, right outcome.

Safe, Compliant Chemical Handling

Allflo’s sealed and magnetic-drive systems protect operators and prevent environmental exposure to corrosive media.

Leak-free, compliant and secure.

Durable Under Pressure

Our pumps feature abrasion-resistant materials, replaceable wear parts and chemical-resistant coatings for extended service life.

Built tough for aggressive process fluids.

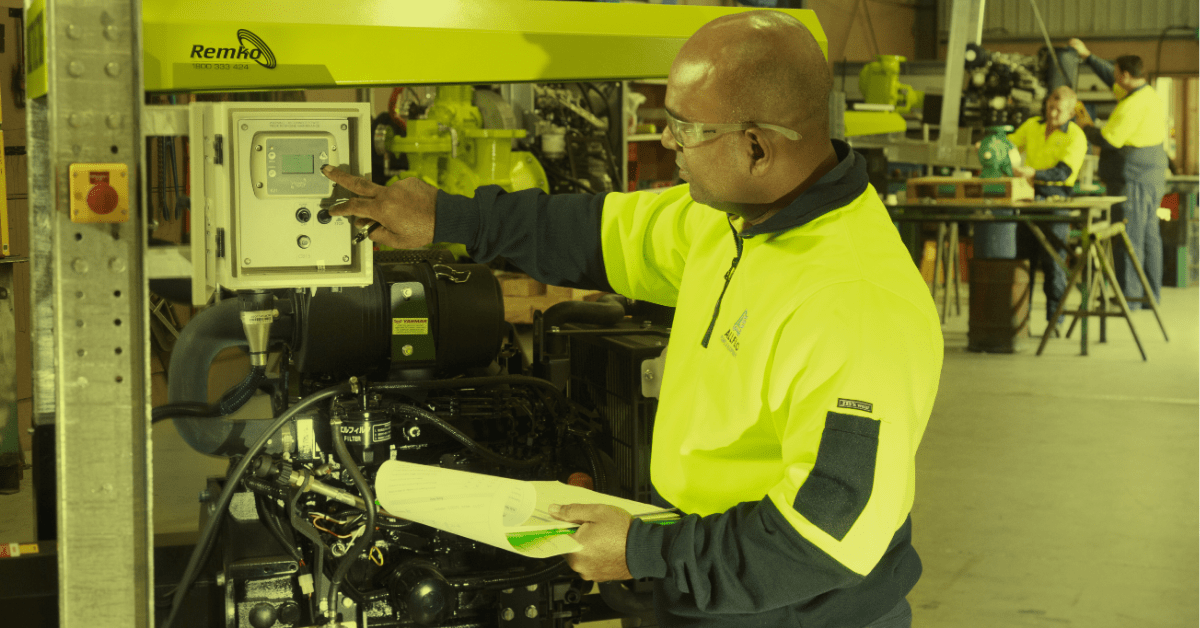

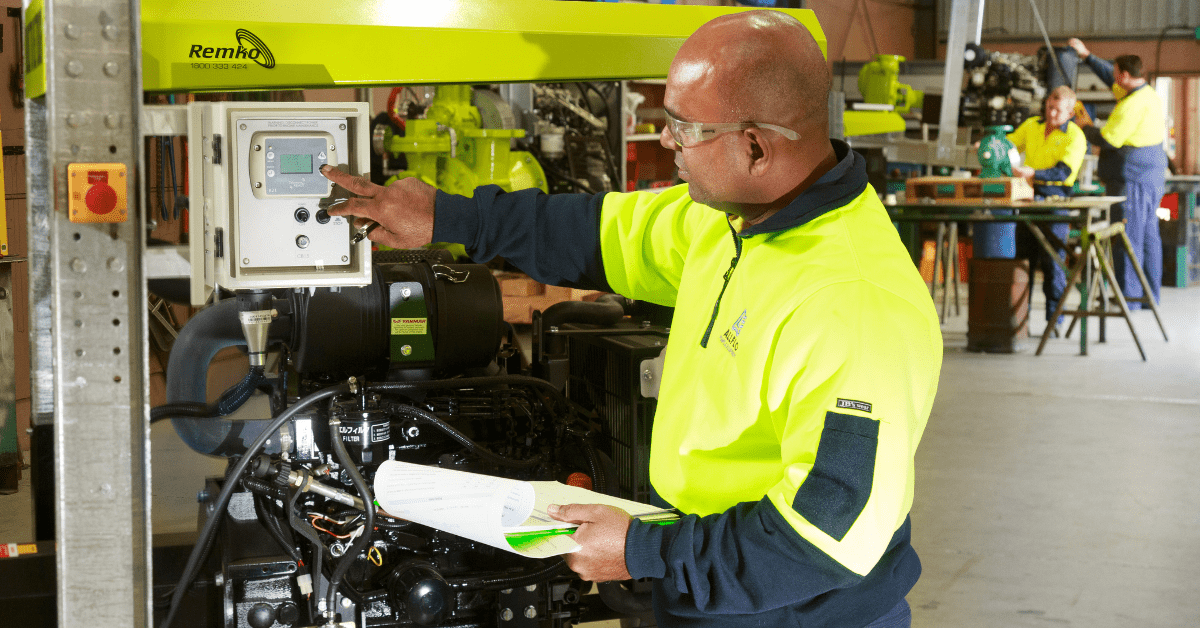

Supported Locally

Our team are always accessible and ready to meet you onsite — from problem-solving to commissioning.

They coordinate maintenance, spare parts, and workshop servicing to keep your systems operating reliably and efficiently.

Reliable support, built in.

FAQ's

for Pulp, Paper & Timber processing

-

Can your pumps handle fibrous pulp and slurry?

Yes — our slurry, screw and progressive cavity pumps are purpose-built to transfer fibrous and viscous materials without clogging.

-

Do you supply pumps for chemical and adhesive transfer?

Absolutely. We supply magnetic drive, diaphragm and peristaltic pumps for safe, leak-free transfer of adhesives, bleach, resin and chemicals.

-

Are your pumps suitable for continuous-duty operation?

Yes — our systems are designed for high uptime and efficiency in 24/7 pulp and timber processing environments.

-

Can Allflo design complete packaged systems?

We can. Our packages are assembled and tested locally with full documentation, containment, controls and performance certification.

-

Do you provide local maintenance and parts support?

We supply spare parts nationwide and offer in-house servicing at our Shepparton workshop. For urgent jobs, our staff can travel to site when required.

Businesses like yours are solving these challenges

Quarry Site Efficiency Upgrade

Problem: Frequent pump breakdowns were delaying production.

Solution: Allflo supplied abrasion-resistant self-priming pumps.

Result: 40% reduction in downtime and servicing.

Custom Fire Water Storage Tank

Problem: A unique site footprint needed a space-efficient, compliant solution.

Solution: We delivered a customised & compliant tank with documentation.

Result: Full compliance and efficient use of space.

NT Mining Fire Protection System

Problem: A mining operation needed a fire system in extreme conditions.

Solution: Allflo delivered a diesel-driven fire system with remote monitoring.

Result: Reliable protection with site-specific performance.