1 min read

How Pumps Are Used At Quarries

Quarries are demanding environments where water management, chemical handling, and dust control are critical to safety and productivity....

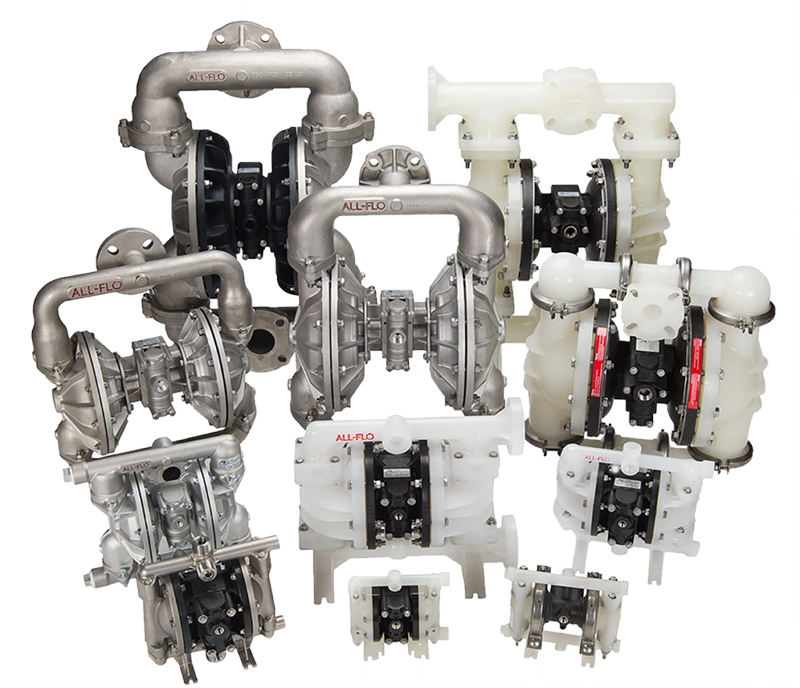

Air Operated Double Diaphragm (AODD) pumps are often associated with low-viscosity transfer duties. In reality, when correctly applied, they can reliably handle high-viscosity fluids across a wide range of industrial applications.

Rather than relying on assumptions, this article outlines a practical, system-based approach to evaluating whether an AODD pump can perform effectively with viscous media.

Air Operated Double Diaphragm (AODD) pumps are often associated with low-viscosity transfer duties. In reality, when correctly applied, they can reliably handle high-viscosity fluids across a wide range of industrial applications.

Rather than relying on assumptions, this article outlines a practical, system-based approach to evaluating whether an AODD pump can perform effectively with viscous media.

When assessing any AODD application involving viscous fluids, three fundamental questions must be answered:

Can the pump draw fluid at the required flow rate?

Can the pump overcome the system’s total dynamic head (TDH)?

How should the pump be de-rated for viscosity?

Each of these is influenced as much by pipework and system design as by the pump itself.

Consider a simple transfer system moving 20 gallons per minute (GPM) using a 1-inch AODD pump handling a viscous fluid.

This example illustrates how changes in pipe diameter and system configuration can determine whether the application succeeds or fails.

The first step is assessing suction line loss.

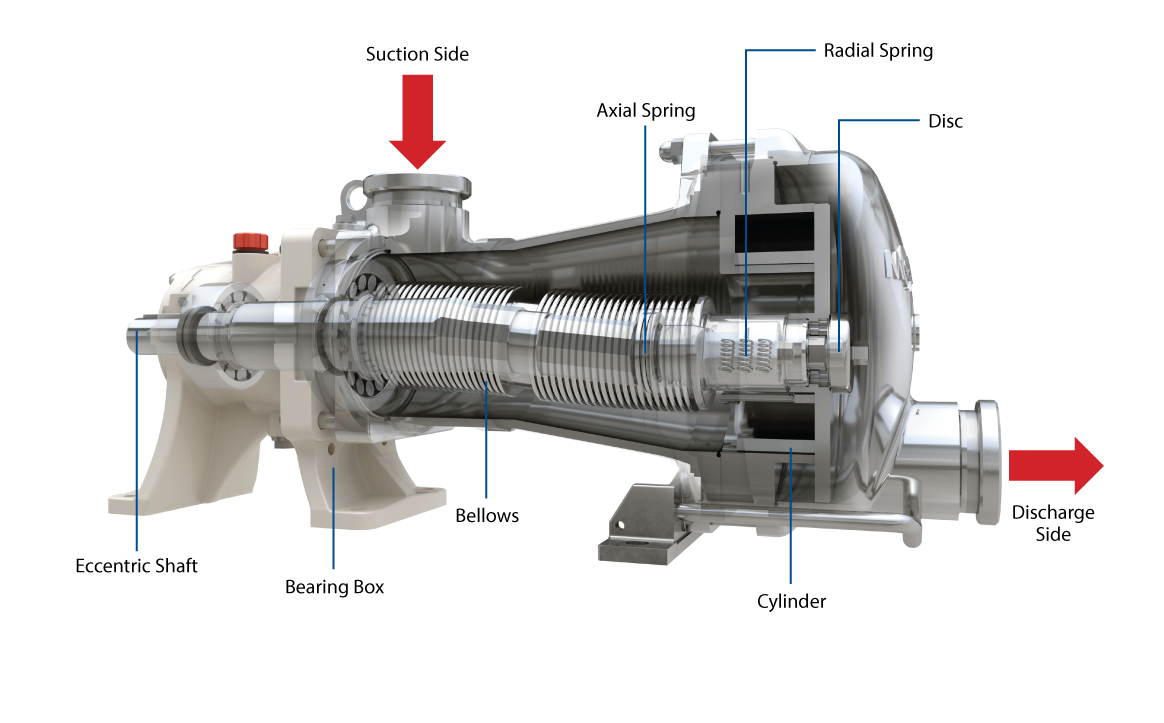

AODD pumps rely on suction lift rather than mechanical priming. If suction losses exceed the pump’s dry-lift capability, the pump will not achieve the desired flow rate.

Key considerations:

Typical 1-inch AODD pumps have a dry lift capability of approximately 15 ft-H₂O (≈ 6.5 psi).

If suction line losses exceed this value, performance will be severely limited.

Example outcome:

A 1-inch suction line produced excessive loss, exceeding the pump’s suction capability.

Increasing the suction line diameter to 2 inches reduced losses from 34 psi to 2 psi, bringing the system back within operational limits.

Takeaway:

Suction line diameter is often the single most critical factor when pumping viscous fluids.

For AODD pumps, TDH is best evaluated in pressure (psi) rather than metres or feet of head, as the energy source is compressed air.

TDH includes:

Static head

Discharge pipe friction losses

Fluid specific gravity

Example outcome:

A 1-inch discharge line produced friction losses exceeding 120 psi, beyond most AODD pump limits.

Increasing discharge diameter to 1½ inches reduced losses to approximately 24 psi.

When combined with static head, the total system TDH was approximately 31 psi — well within the pump’s operating range.

Design guidance:

For pump longevity, Allflo recommends designing systems to operate mid-range, not at maximum pressure.

Manufacturers publish pump curves based on water. As viscosity increases, flow rate decreases due to internal friction losses.

Example correction:

At 1,500 cP, the pump operated at approximately 88% of its published capacity.

To achieve 20 GPM, the pump must be selected based on 23 GPM on the water curve.

This correction ensures real-world performance aligns with expectations.

Using manufacturer pump curves:

Flow rate is plotted against system pressure (TDH).

Air inlet pressure and air consumption are derived from the curve.

Example outcome:

Required air inlet pressure: ≈ 55 psi

Air consumption: ≈ 22 SCFM

Exceeding required air pressure can cause cavitation, as suction losses may surpass pump capabilities.

AODD pumps can handle viscous fluids effectively when system design is optimised

Pipe diameter has a greater impact than pump size in many applications

Suction losses, TDH, and viscosity de-rating must be evaluated together

Oversupplying air pressure can be just as damaging as undersupplying it

This example highlights Allflo’s approach to pump selection:

practical engineering, system-first thinking, and reliable outcomes — not guesswork.

If your operation is handling viscous fluids and performance is inconsistent, the issue is often the system, not the pump.

If you’d like help assessing a high-viscosity application, Allflo’s team can review your system and recommend a practical, long-term solution.

1 min read

Quarries are demanding environments where water management, chemical handling, and dust control are critical to safety and productivity....

2 min read

Whether you’re assessing an existing industrial pump system or planning a new installation, flow rate is one of the most important performance...

1 min read

Efficiency, reliability, and product recovery are critical in modern food production. In many processing facilities, liquids are transferred...