1 min read

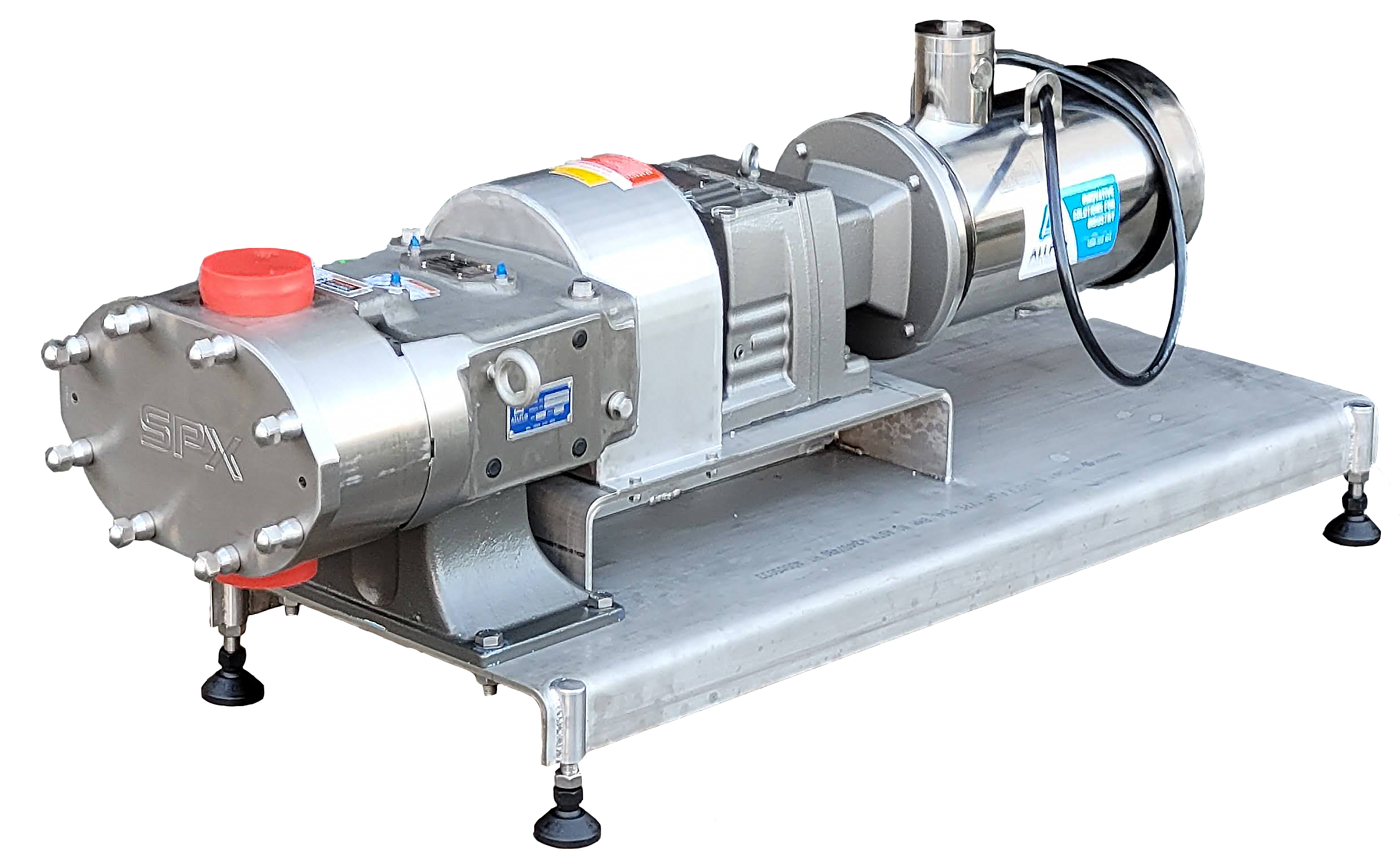

Custom Pump Base Design for Global Leader in the Dairy Industry

Allflo Pumps & Equipment was engaged by a global leader in the dairy industry to deliver a reliable pumping solution for transferring a viscous,...

This pump upgrade demonstrates how targeted engineering improvements can significantly improve reliability and extend service life in demanding industrial environments.

In this application, the pump was operating under sustained high pressure and temperature conditions, leading to repeated seal failures and unplanned downtime. Rather than replacing the pump entirely, Allflo assessed the failure points and implemented targeted engineering upgrades — including improved sealing arrangements and materials better suited to the operating conditions.

The result was a significantly more robust pump assembly, reduced maintenance intervention and a substantial extension of service life.

These improvements quadrupled the pump's life.

This kind of targeted upgrade allows existing assets to perform reliably in harsh conditions, without the cost and disruption of full replacement.

1 min read

Allflo Pumps & Equipment was engaged by a global leader in the dairy industry to deliver a reliable pumping solution for transferring a viscous,...

1 min read

Project focus: Trade waste pumping reliability, solids handling and lifecycle value in food processing environments. As a Queensland abattoir...

1 min read

Allflo Pumps & Equipment was engaged to deliver an emergency back-up pumping solution for the reverse osmosis (RO) desalination plant on the island...