Why Are There Holes in a Pump Impeller?

A practical explanation of balance holes, axial thrust & pump reliability.

Pump impellers aren’t drilled with holes by accident.

Those holes—known as balance holes—are a deliberate engineering solution used to control internal forces, protect bearings and seals, and extend pump service life in real-world operating conditions.

This article explains why balance holes exist, what problem they solve, and how they contribute to reliable, long-term pump operation in real-world applications.

The short answer

The holes in a pump impeller are there to reduce axial thrust—a force that pushes the impeller along the shaft and places stress on bearings, seals, and internal components.

Without proper control of this force, pumps suffer from premature wear, higher maintenance costs & reduced service life.

Understanding the forces inside a centrifugal pump

A well-designed centrifugal pump manages several dynamic forces during operation.

Of these, two are critical:

Axial forces

Axial forces act parallel to the centreline of the shaft, pushing the impeller either toward or away from the suction side of the pump.

Radial forces

Radial forces act at right angles to the shaft, pulling the impeller sideways depending on operating conditions and flow.

Both forces exist in every centrifugal pump. Good pump design doesn’t eliminate them—it controls them to prevent damage and premature wear.

Why do axial forces occur?

Axial forces are created by pressure differences across the impeller.

In simple terms:

-

One side of the impeller is exposed to higher pressure than the other

-

That pressure imbalance generates a force along the shaft

-

The largest contribution comes from pressure acting on the impeller shroud

Depending on the impeller design (open, semi-open, or closed), this force can be significant.

Key takeaway: Axial forces are created by pressure imbalance across the impeller, not by pump size or speed alone.

How impeller design helps neutralise axial forces

There are several proven engineering methods used to manage axial thrust:

1. Opposed impellers (multistage pumps)

In large multistage pumps, impellers can be arranged to face opposite directions.

For example:

-

Three impellers face one way

-

Three face the opposite way

This balances axial forces across the shaft.

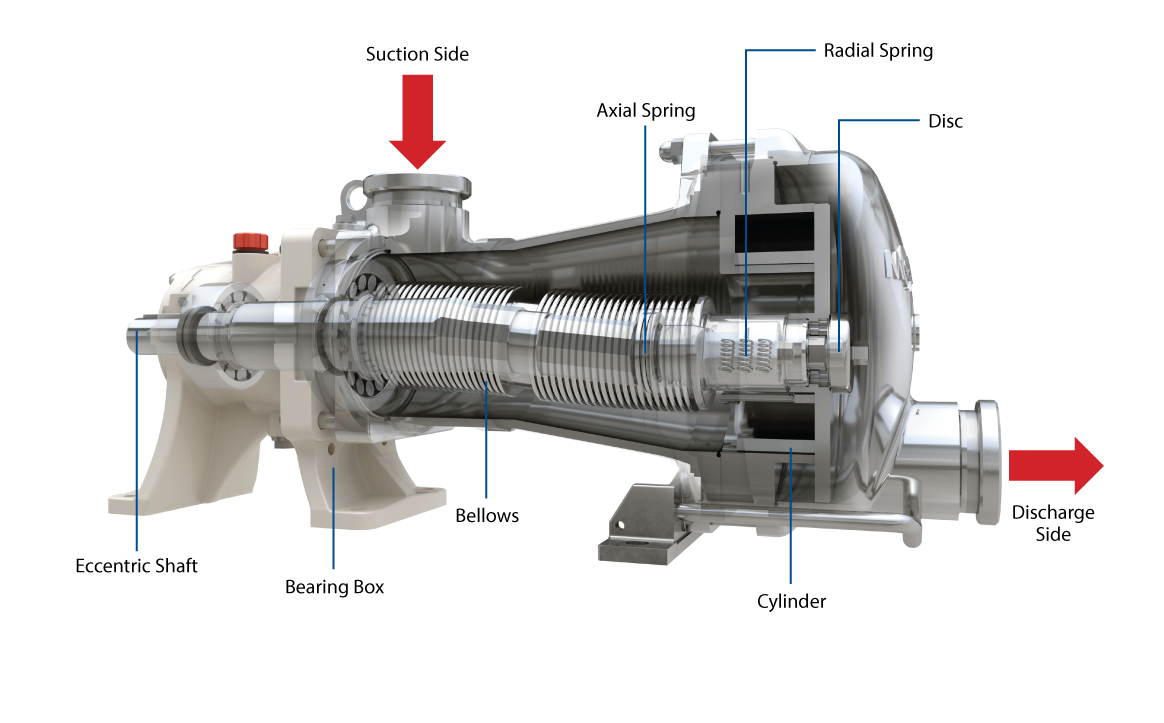

2. Balance drums or discs

Common in high-pressure multistage pumps, balance drums absorb axial load before it reaches the bearings.

3. Double-suction impellers

Impellers with two inlet eyes positioned 180° apart balance pressure evenly across the impeller, significantly reducing axial thrust.

Why balance holes are used in end-suction pumps

In the broader pump market, the majority of end-suction pumps use semi-open or single-shroud impellers. These are popular because they:

-

Are more cost-effective to manufacture

-

Perform well across a wide range of applications

However, this design creates a downside:

higher unbalanced axial forces acting toward the suction end of the pump.

In some operating conditions, axial thrust in end-suction pumps can reach hundreds of kilograms of force, placing heavy load on thrust bearings.

The problem with “just using bigger bearings”

One way to handle axial thrust is to install larger thrust bearings.

But this introduces new issues:

-

Larger bearings require larger shafts and housings

-

Pump size and cost increase

-

Maintenance and replacement costs rise

-

Efficiency and compactness are compromised

This is not always the most practical or economical solution.

For many industrial applications, this approach solves the symptom rather than the cause—and increases total cost of ownership.

Why balance holes are the smarter solution

Balance holes drilled into the impeller shroud allow high-pressure fluid to equalise across the impeller.

The result:

-

Axial thrust is significantly reduced

-

Bearing loads are lowered

-

Seal life improves

-

Overall pump reliability increases

Yes, balance holes cause a very small efficiency loss—but it is negligible compared to the gains in durability and service life. In most industrial applications, the trade-off is more than justified.

Key takeaway: Balance holes reduce axial thrust at the source, rather than compensating for it with larger mechanical components.

Why this matters in real operating environments

Every detail of a pump is engineered for a reason—even the smallest ones.

Balance holes in an impeller are a simple but highly effective way to:

-

Control axial thrust

-

Protect bearings and seals

-

Reduce maintenance

-

Extend pump life

What looks like a minor design feature is actually a critical reliability decision—one that reflects how a pump is engineered for long-term operation, not just initial performance.

Contact a Pump Specialist Today

2 min read

How to calculate the flow rate of your pump

Whether you’re assessing an existing industrial pump system or planning a new installation, flow rate is one of the most important performance...

1 min read

How To Improve Efficiency In Food Production

Efficiency, reliability, and product recovery are critical in modern food production. In many processing facilities, liquids are transferred...