Food & Beverage

Pumps & Equipment

- Hygienic pumps for food, dairy, beverage, and ingredient processing

- Protect flavour, texture, and product integrity

- Fully sanitary materials compliant with FSANZ, HACCP & AS/NZS standards

- CIP/SIP compatible designs for faster changeovers

- Gentle, reliable handling of viscous, shear-sensitive, and particulate products

.jpg?width=2000&height=898&name=BlueTeam_Hero%20(2).jpg)

.jpg?width=2000&height=898&name=BlueTeam_Hero%20(6).jpg)

Built for Hygiene

Built for Hygiene

Protects Product Quality

Protects Product Quality

CIP/SIP Compatible

CIP/SIP Compatible

Handles Thick & Delicate Fluids

Handles Thick & Delicate Fluids

Supported Locally

Supported Locally

Engineered for hygiene. Designed for consistency. Built for trust.

Food and beverage processors rely on pumps that protect product integrity at every stage — from raw ingredients to finished goods.

Allflo delivers sanitary pump solutions designed to handle complex fluids, support CIP/SIP cleaning, and maintain consistent production while meeting strict food safety standards.

Our systems ensure compliance, improve uptime, and help you maintain the quality your customers expect.

Pumps We Build for Food & Beverage

- Product Handling & Transfer

- Dosing, Batching & CIP Systems

- Viscous & Particulate Products

- Waste, CIP Return & Utility Water

- Chemical & Sanitising Fluids

Product Handling & Transfer

Sanitary pump systems for beverages, dairy, sauces, chocolate, creams, and delicate food products — engineered to protect texture, flavour, and product quality.

Explore products:

Chemical & Sanitising Fluids

Corrosion-resistant pumps for detergents, sanitisers, caustics, and CIP chemicals — engineered for safe containment and cleanroom-ready operation.

Explore products:

Waste, CIP Return & Utility Water

Industrial-grade systems for washdown, greywater, CIP return, and wastewater management — supporting hygiene compliance and plant efficiency.

Explore products:

Process & Utility Pumps

Reliable centrifugal and booster systems that support on-site water transfer, tank filling, and wash-down applications — built for everyday performance across civil construction environments.

Explore products:

Dosing, Batching & CIP Systems

Precision systems for acids, additives, enzymes, flavours, and CIP fluids — built for accuracy, repeatability, and food-safe automated processing.

Explore products:

Viscous & Particulate Products

High-viscosity transfer solutions for thick, particulate, or shear-sensitive ingredients — ensuring gentle flow without damaging the product.

Explore products:

What to expect from Allflo Pumps & Equipment

Sanitary by Design

Pumps built with 316 stainless steel, food-grade seals, and hygienic geometry for compliant product handling.

Protects Product Quality

Gentle pumping action preserves delicate ingredients, particles, and textures across the entire process.

Faster, Easier Cleaning

CIP/SIP-compatible designs reduce downtime, manual handling, and changeover times between batches.>

Reliable in Demanding Environments

From viscous chocolate to abrasive food waste, our pumps are engineered to maintain uptime and output.

Local Support, Food-Grade Expertise

Trusted by processors across Australia with reliable service, spare parts, and lifecycle engineering support.

FAQ's

for Food & Beverage

-

Are your pumps compliant with FSANZ, HACCP and food-grade standards?

Yes — we specify fully sanitary materials, food-safe elastomers, and hygienic pump designs.

-

Can your pumps handle viscous or shear-sensitive products?

Yes — lobe, progressive cavity, and peristaltic pumps are ideal for thick or delicate ingredients.

-

Are your pumps compatible with CIP and SIP?

Yes — many of our food processing pumps are engineered for CIP/SIP cleaning and fast changeovers.

-

Can you provide complete skid packages?

Do you supply pumps for additives, acids and dosing?

-

What about wastewater and plant washdown?

We supply submersible, vortex, and grinder pumps for washdown water, CIP return, and waste streams.

Businesses like yours are solving these challenges

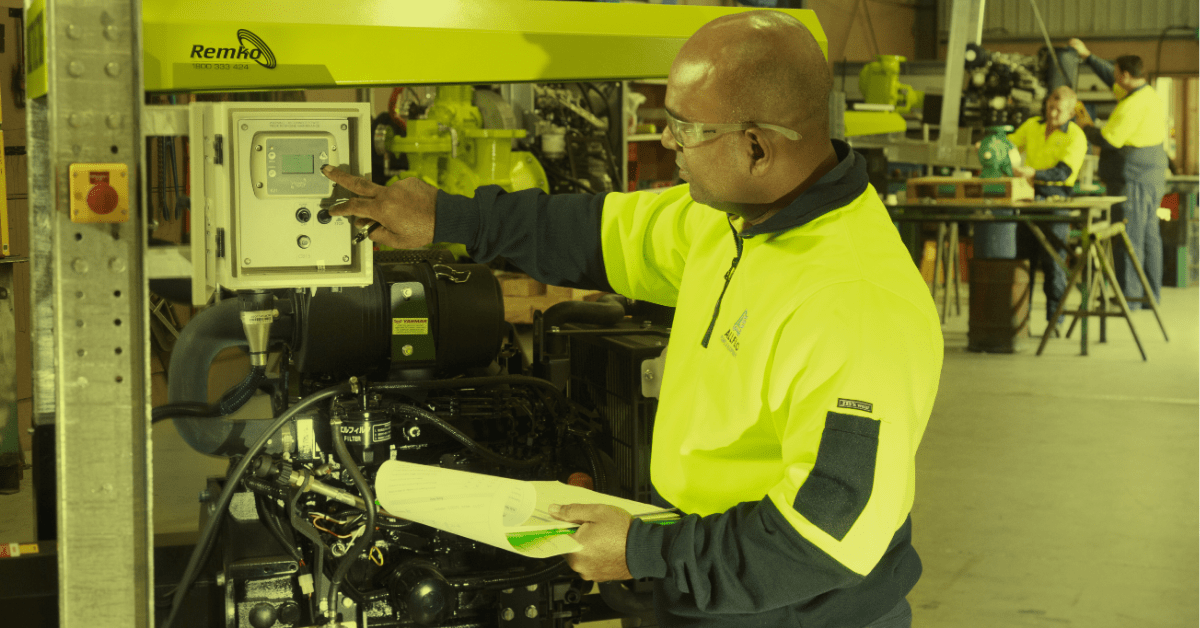

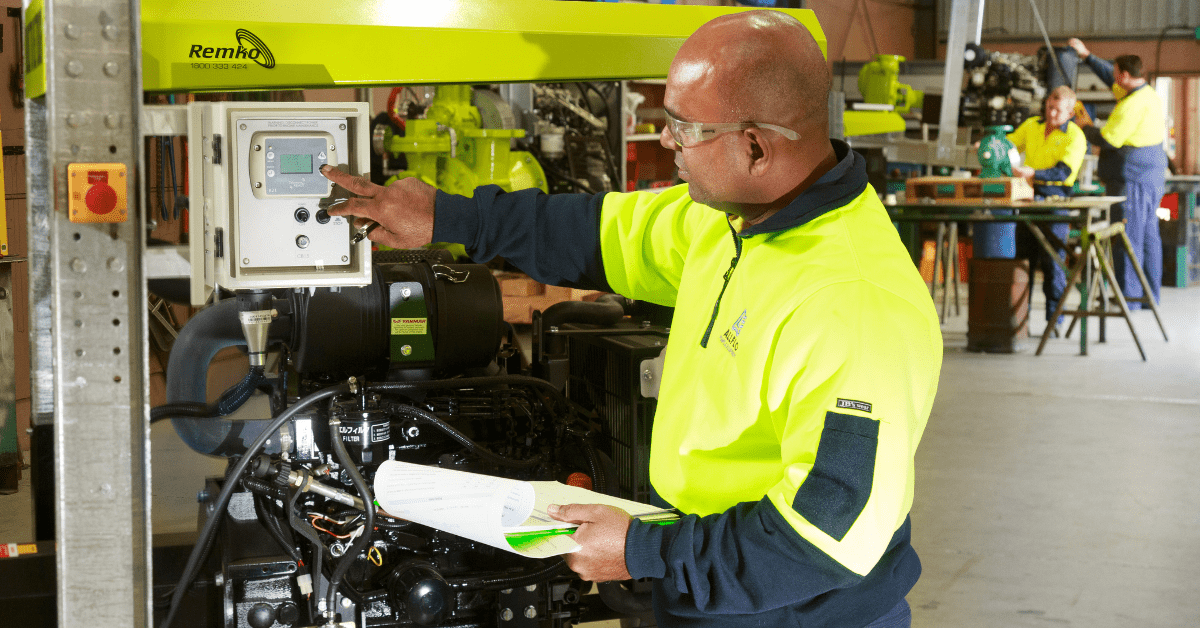

Quarry Site Efficiency Upgrade

Problem: Frequent pump breakdowns were delaying production.

Solution: Allflo supplied abrasion-resistant self-priming pumps.

Result: 40% reduction in downtime and servicing.

Custom Fire Water Storage Tank

Problem: A unique site footprint needed a space-efficient, compliant solution.

Solution: We delivered a customised & compliant tank with documentation.

Result: Full compliance and efficient use of space.

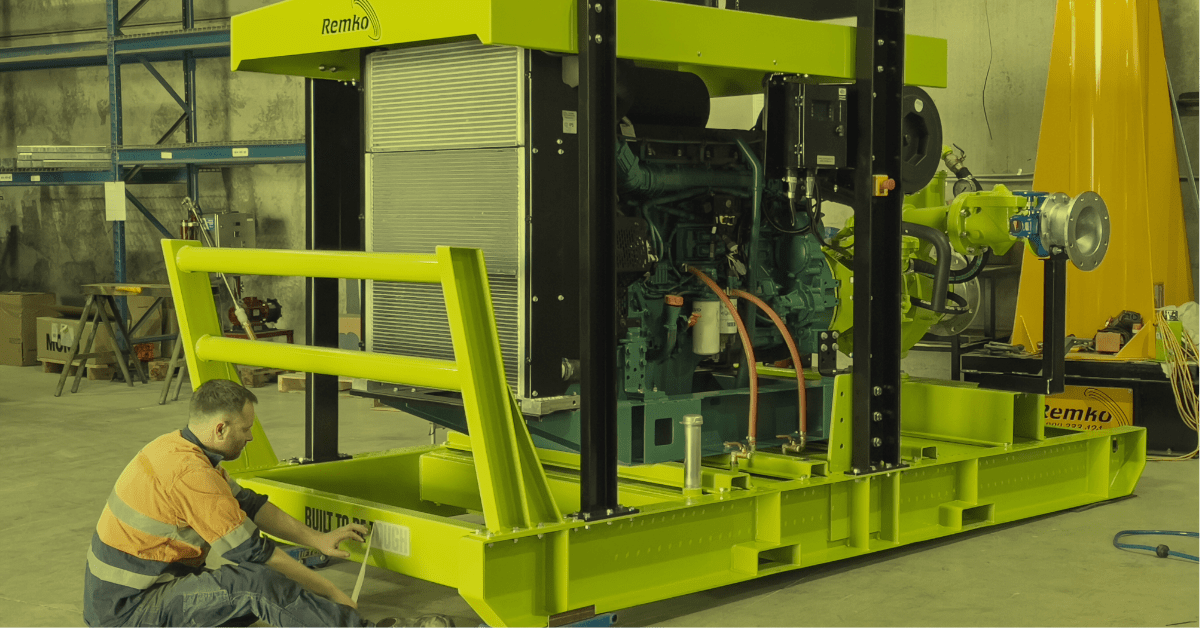

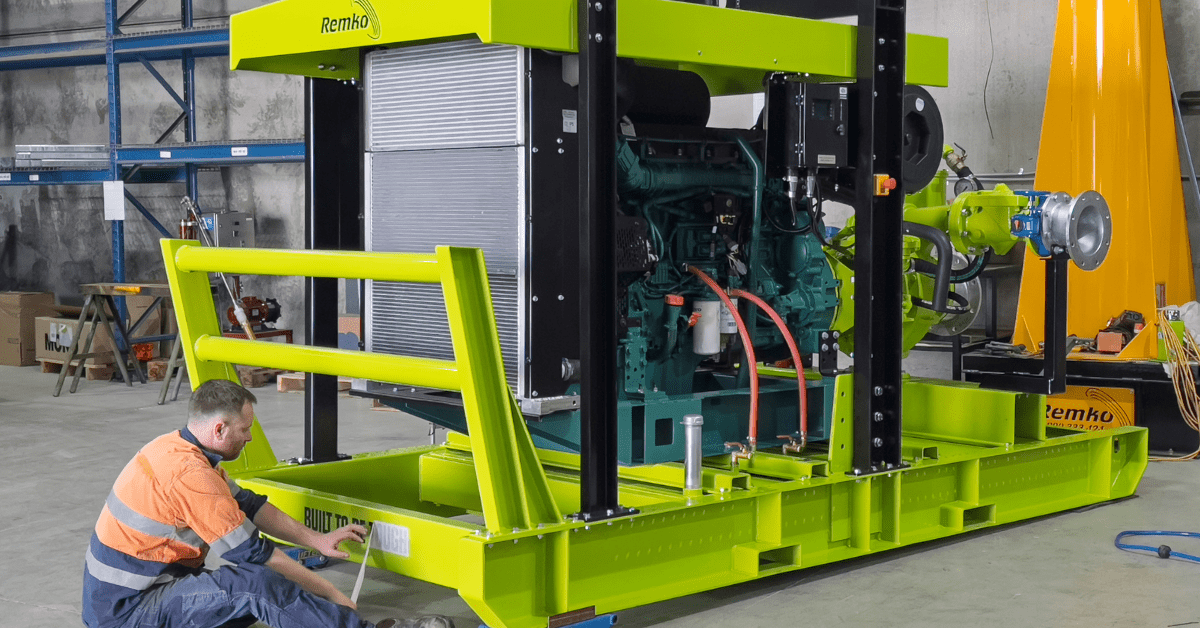

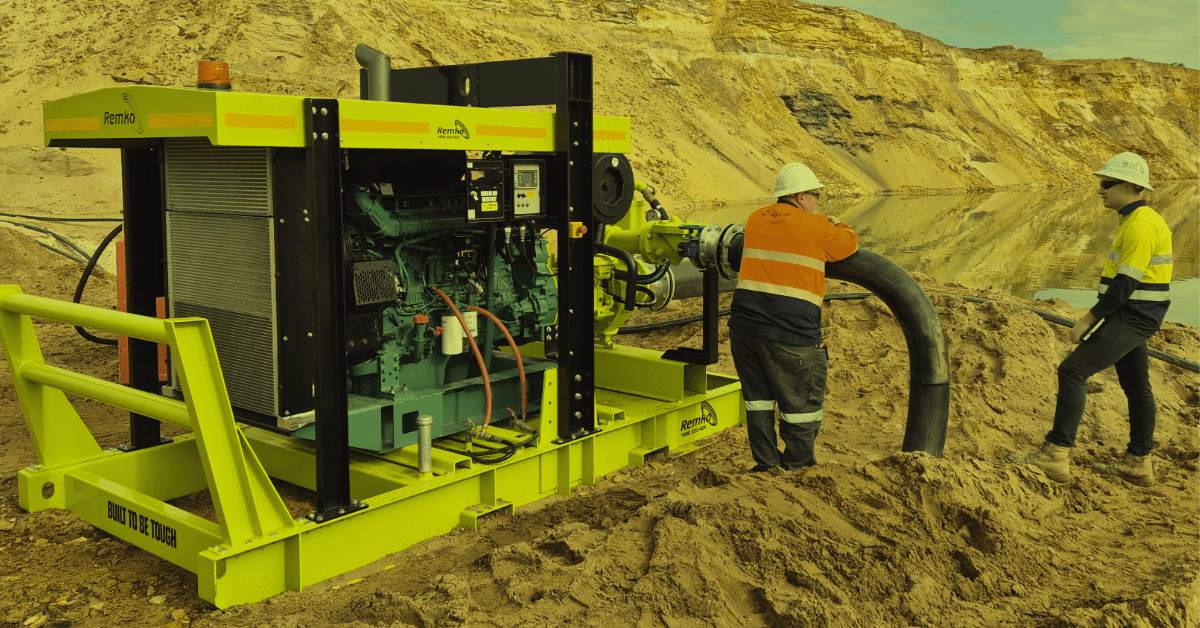

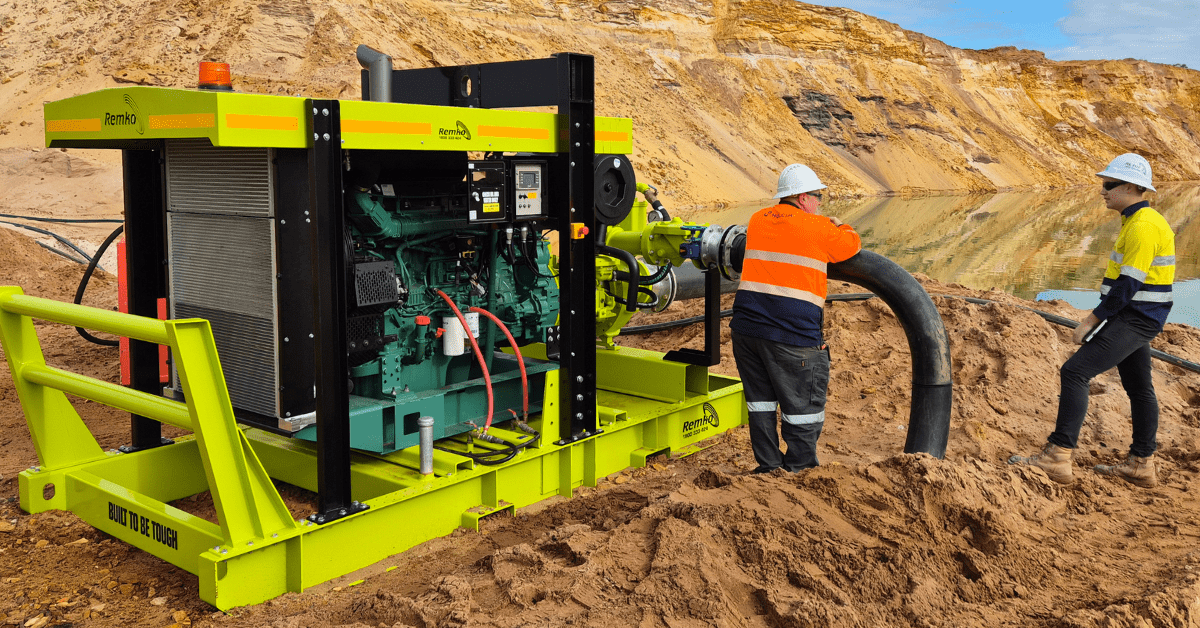

NT Mining Fire Protection System

Problem: A mining operation needed a fire system in extreme conditions.

Solution: Allflo delivered a diesel-driven fire system with remote monitoring.

Result: Reliable protection with site-specific performance.